Pulverizer Wikipedia

COAL FEEDER, PULVERIZER DAN COAL BURNER

WhatsApp)

WhatsApp)

COAL FEEDER, PULVERIZER DAN COAL BURNER

Earliest known coal feeder, representing innovations that influenced nearly all industries using coalfired boilers A variety of mechanical feeders, including dragchain conveyors and rotary pocket feeders, historically have been used to volumetrically control the flow of fuel to coal pulverizers .

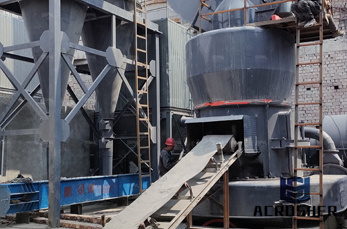

Nov 17, 2012· pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner ...

Feeder Crusher Dryer o PrimaryAir Fan Pulv Coal To Burners Classifiers Il''''L9. Tube Mill (Double Ended) Rating D pr O Raw Coal Silo Feeder Crusher Dryer Figure 9. Mill System Components AIRFUEL (AE) RATIO FOR ESTIMATING PRIMARY AIR FLOW FOR ALL BITUMINOUS a SUBBITUMINOUS COALS VS TOTAL MOISTURE IN COAL

A Coal Pulverizer In A Power Plant. Coal Mill Pulverizer In Thermal Power Plants. Pulverizermill system one of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill the coal flow is controlled by the feeder allowing coal to flow into the pulverizer mill. Chat ...

Volumetric Coal Feeder is used in this plant. The purpose of a RC feeder in the coal pulverizing circuit is to feed the raw coal from the bunker into the pulverizer in controlled and varied quantities corresponding to the boiler load demand. Volumetric Coal Feeder is used in this plant. Major problem areas of R C Feeders observed during study: 1.

1. The majority of worldwide power boilers use pulverized coal. Stock High Pressure Gravimetric Feeders reliably and accurately deliver raw coal to each pulverizer in exact response to boiler fuel demands. 2. Utilities and Independent Power Producers specify Fluidized Bed Boilers for a growing number of installations.

DESCRIPTION. Pelatihan ini berkaitan dengan penerapan prosedur dan pelaksanaan pembongkaran, pembersihan, identifikasi kerusakan dan pemasangan kembali yang dibutuhkan pada Pemeliharaan Coal Feeder dan Pulverizer PLTU Batu Bara sesuai standar Perusaan.

pulverizer design eand plosion proof safety requirements. Pulverizer Design Eand Plosion eand plosion proofing coal crusher house design . Get p. hazards in a coal pulverizer Sep 2, 1992 A safety system for a coal pulverizer (12), the safety system (8) comprising: . the coal, in damage to the power plant, and in . More

Dry coal that is allowed to remain in the pulverizer system can spontaneously ignite. Raw coal to the pulverizer must be uninterrupted and controllable. Precise feeder control and minimal stoppages above and below the feeder are crucial. Hot smoldering or burner raw fuel anywhere in the pulverizer system is considered serious.

Feb 08, 2018· Pulverized coal is the most widely used fuel in the steel sector. Watch how its selection, pulverization and quality check using a bomb calorimeter is key to an energy efficient system.

Pulverized Coal Pipe Testing and Balancing – 201653 · Pulverized Coal Pipe Testing and Balancing By Richard F. (Dick) Storm, PE The first step in optimizing combustion system performance is balancing the air and fuel flowing through(DOC) COAL FEEDER, PULVERIZER DAN COAL BURNER COAL FEEDER, PULVERIZER DAN COAL .

The Model 496 NFPA rated Gravimetric coal feeder is designed to meet your needs when feeding a pulverizer. It is designed with the operator in mind to give years of trouble free operation. Expert Advice Call: +1

crusher coal pattern. horizontal coal pulveriser pattern santhosanl. horizontal coal pulveriser pattern greenrevolutionorgin Coal Pulverisers Global Solutions920 Кб Engineering for life Fossil Fuel >Coal Pulverisers Committed to servicing the power generationsize, profile and .

Coal pulverizers are the heart of a pulverized coalfueled boiler. Often, the root causes of nonoptimized combustion lie with the pulverizers. ... Retrofitting gravimetric coal feeders with new ...

Raw Coal Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a directfired coal burning system. 1 EPRI study on large coal fired utility boilers (greater than 600MW) using pulverizers with capacities greater than 50 tons per hour Combustion Engineering 783RP BowlMill Coal ...

Explosions consistently occur when the coal air mixture is leaner than normal, either when initating coal feed on mill startup, stopping coal feed on shutdown, or when equip ment problems cause inadvertent loss of feed. Upon loss of feed to a pulverizer, the coal/ air mixture in the system becomes leaner and the coal dust will

Coal feeder inlet and coalbunker outlet gates are open. ix. Pulverizer outlet temperature less than a high limit recommended by the manufacturer. x. Pulverizer lubricating oil pressure, if provided, is healthy. xi. Primary air pressure adequate. xii. Differential pressure between pulverizer under bowl and seal air header is adequate. xiii.

Pulverizer For Rolling Mill System. peat consists of coal pulverizers. Pulverized Fuel Handling Systems Unit, Central System . Hot air or fire gases are passed through the feeder to dry the coal before feeding to the pulverizer. The pulverized coal is carried from the mill with the help of primary air fan.

The ELtype pulverizer is a higher capacity pulverizer when compared to the original Etype pulverizer of the same size. E to EL conversions have significantly improved the availability, capacity, and reliability of Etype pulverizers. The ELtype pulverizer is also much less prone to coal dribble problems due to an improved bottom grinding ...

May 02, 2020· Coal Feeder is a device that regulates the amount of coal to be supplied into the Coal Mill. The amount of coal is regulated according to the needs in the boiler combustion chamber (furnace). The number regulation system in the coal feeder can be done in two ways based on the type, namely by weight fraction or coal volume fraction.

Our skilled technicians have the power and expertise to handle everything from preventative maintenance to major coal pulverizer overhauls to keep your mills running smoothly and efficiently. We supply all basic tooling, labor and supervision to repair any part of the pulverizer from the gearbox to the raw coal feeder.

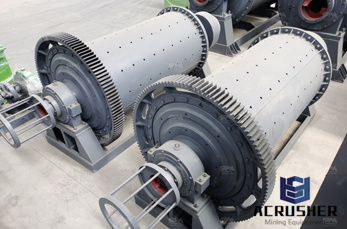

FOR COAL PULVERIZATION IS THE MOST PREFERRED AND UTILIZED MILL. The capacity in #/hr. of the mill is calculated on the assumption that the coal hardness is 55 on the Hardgrove Grindability Index and has a moisture content of 8%. This would then produce and output based on 70% of the coal passing through a 200 mesh screen.

Dec 11, 1979· Power plant boiler fuel demand is transmitted as a coal feeder speed demand to a coal pulverizer control. A speed controller operates the feeder in accordance with the speed demand, and a position controller for a hot coal transport air damper positions the hot air damper to hold the mill outlet temperature to a setpoint value and to increase or decrease damper position in accordance with a ...

WhatsApp)

WhatsApp)