35 Best Coking coal images | Coking coal, Coal miners ...

Sep 20, 2018 Explore dk_u20''s board "Coking coal" on Pinterest. See more ideas about Coking coal, Coal miners and Coal mining.

WhatsApp)

WhatsApp)

Sep 20, 2018 Explore dk_u20''s board "Coking coal" on Pinterest. See more ideas about Coking coal, Coal miners and Coal mining.

Sponge iron is produced primarily both by using noncoking coal and natural gas as reductant and therefore classified as coal based and gas based process respectively. Due to promising availability of coal of 264,535 million tonnes the coal based sponge iron plants share the major amount of its production . At present, there are 118 large and ...

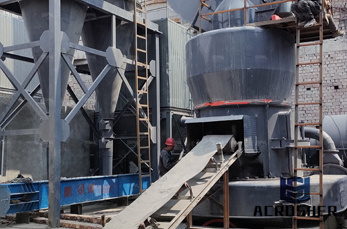

High Quality Line Factory Cement, Find Complete Details about High Quality Line Factory Cement,Roasted Molybdenum Concentrate Bauxite Production Line Coking Coal Price,Roasted Molybdenum Concentrate Bauxite Production Line Coking Coal Price,Cement Making Machinery Plant Roasted Molybdenum Concentrate from Supplier or ManufacturerBeijing Kaidong Machinery Co., Ltd.

Dec 28, 2010· essentially no Indiana coal is being used for coke production. In 2002, Indiana''s steel industry used an estimated million tons of coal. Of this, approximately million tons was used for coke Essentially all of this coking coal comes from Kentucky, West ia and ia.

The industrial production of coke from coal is called coal is baked in an airless kiln, a "coke furnace" or "coking oven", at temperatures as high as 2,000 °C (3,600 °F) but usually around 1,000–1,100 °C (1,800–2,000 °F). This process vaporizes or decomposes organic substances in the coal, driving off volatile products, including water, in the form of coalgas and coaltar.

Soft coal is widely used in coking, coal blending, power boiler and gasification industry. Hard coal: Blind coal is in powder or little bulk shape, in black color with shining metallic luster. The coal has low impurity, high content of fixed carbon (over 80%); the coal has low volatile component of .

SORT BY Cetagories. excavator vertical digging system bobcat pictures; vertical shaft kiln vertical coal mills mini; coking coal production vertical shaft process . 87144. 34231. 87110. 34231. 87144. 32220. 87110. Complete OFO Version 2017 OFO Code Description 20171 MANAGERS Managers plan, direct, coordinate and evaluate the ...

As well as from lump, briquette. And whether process production of coal is horizontal, or vertical. There are 3,597 process production of coal suppliers, mainly located in Asia. The top supplying countries or regions are China, Ukraine, and Thailand, which supply 99%, 1%, and 1% of process production of coal respectively.

productivity. The process is also characterized by flexibility regarding various raw materials, including iron ore fines, steel mill waste and noncoking coal. This paper outlines the features and development status of Kobe Steel''s coalbased reduction processes, each employing an RHF for reducing carbon composite agglomerates.

Process technology adoption in European coal, : Mechanical ventilation in coal mines ... among many in the coal production process, albeit an important one. If other constraints had not ... Verticalentrance shaft mines required a stronger method of ventilation. Here mine

Excavation Methods. Vertical Shafts. There are 4 methods in general use: Conventional drill, blast remove stone ("muck out") to surface with a the shaft is to be "lined" ( sides to be covered with a concrete or even a steel lining), this is normally placed as the shaft is excavated.

Early Turn Of The Century, Elevator, in Vertical Shaft. Image Search Results for coal miners Image result for mining shaft elevator 1800''s Butte MT ... Ut The largest coking coal deposits in the West were in Carbon County. Built in the to process the coking coal for the production of steel, hundreds of neatly aligned coke ovens now stand in ...

Global steel production is dependent on coal. Over 71% of the steel produced today uses coal. Metallurgical coal – or coking coal – is a vital ingredient in the steel making process. World crude steel production was billion tonnes in 2017.

Coal, either as coal fines or as coal briquettes, is introduced into a coking chamber and is thereat exposed to microwave radiation to transform the coal into hot coke. Preferably, the microwave radiation is at a frequency of from twenty to 3000 MHz. The hot coke is then passed to a cooling zone whereat photocells absorb radiant energy from the hot coke and transform the thus absorbed radiant ...

The coal industry has undergone a remarkable transformation over the last three decades. During this time, coal production has doubled, while the number of active miners has been halved and the number of mines has dropped by a factor of three ().This has resulted in the concentration of production in a smaller number of larger mines.

coking coal process. coking coal process XSM excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (coking coal process) in more than one hundred of the worldsales of countries and regions.

In this latter type of coking process the coal is preformed frequently by briquetting or extrusion methods and then coked. The spherical agglomeration process produces an intimately blended feed containing tar of low mineral and pyrite content. ... The briquettes whether produced hot or cold can then be fed to the vertical shaft carbonization ...

Jan 17, 2019· Coke is produced by igniting bituminous coal under reduced oxygen conditions in oven batteries specially designed for this process. The coking process .

volatiles are driven from the coal to form coke. When coking is completed, a pusher machine on one end of an ... continuous coking process < Costeffective coke quenching and dust ... • The Ukrainian State Research Institute for Carboc hemistry is testing a continuous cokemaking process using a vertical shaft structure and a piston to push ...

The mine run coal is crushed to a size for coking coal requirements. The entire production is treated over a coal jig which removes as waste primarily the coarse refuse. The coarse clean coal passes over the jig along with the fines and is elevated to a wedge bar stationary screen with 1 .

• Process of coal selection – Single coal analysis – Pilot Coke Oven tests, ... • indicator of coal coking ability, not additive for coal blend ... Coke – nature, production, applications and coking coal required Author: Kruger, Hannes Created Date:

DELAYED COKING PROCESS. Description: Delayed coking process is a thermal process which increases the molecular aggregation or association in petroleumbased residues or coal tar pitches leading to extended mesophase domains. This is achieved by holding them at an elevated temperature (usually 750 K–765 K) over a period of time (12 to 36 h).

P. GoldsWorthy, ... E. On, in The Coal Handbook: Towards Cleaner Production: Coal Utilisation, 2013. Wall pressure and battery life. During the plastic stage of the coking process swelling of the coal mass can arise due to the inability of volatile emissions to easily escape. Swelling can impart pressure to the refractory walls of the ...

COKE PRODUCTION The cokemaking process involves carbonization of coal to high temperatures (1100°C) in an oxygen deficient atmosphere in order to concentrate the carbon. The commercial cokemaking process can be broken down into two categories: a) Byproduct Cokemaking and b) NonRecovery/Heat Recovery Cokemaking. A brief description of each coking

WhatsApp)

WhatsApp)