Cement packing plant YouTube

Jan 25, 2011· A tour through the process of packing cement in 50 kg bags, at the Ramliya II cement plant i Egypt. The paking machines is supplied by Ventomatic. The packing plant consist of three packing ...

WhatsApp)

WhatsApp)

Jan 25, 2011· A tour through the process of packing cement in 50 kg bags, at the Ramliya II cement plant i Egypt. The paking machines is supplied by Ventomatic. The packing plant consist of three packing ...

LOESCHE CCG Plant for Siam City Cement Sri Lanka. Galle LOESCHE is supplying a CCG grinding plant for Siam City Cement Ltd. (Lanka) which will be used in the harbour area of Galle on the southern tip of Sri Lanka as part of an expansion of the Ruhunu cement plant.. A wide variety of cement types can be produced with the compact CCG grinding plant.

Find here Cement Packing Machine, Cement manufacturers, suppliers exporters in India. Get contact details address of companies manufacturing and supplying Cement Packing Machine, Cement , Cement Packing Machinery across India.

Cement grinding and packing process. The clinker is ground with an amount of gypsum to a fine powder in order to regulate the setting time of cement and to gain the most important property of cement, which is compressive strength.

The cement producer will procure cement from its subsidiary Trinidad Cement, according to the Jamaica Observer newspaper. Caribbean Cement has reported technical issues with its packing plant which have led to it being unable to support the local retail market. It has also suspended all exports.

Kyrgyzstan: Kant Cement has upgraded its packing equipment at its integrated plant. Russia''s Vselug supplied a Turbo K8 filling machine and Germany''s Berg provided compressors, according to Cement and its Applications magazine. The company plans to sell at 60% of its products in 25kg and 50kg following the upgrade.

FIXED PACKING MACHINE. Impeller stationary type packaging machine mainly include the machine body, feeding mechanism, control mechanism, the microcomputer weighing mechanism, bag hang mechanism,etc. This type of machine can be not only used for cement packaging, but also for packaging of other powder, granular materials with good liquidity.

Cement is a fine powder, obtained from the calcination at 1,450°C of a mix of limestone, clay, and iron ore. The product of the calcination process is clinker—the main ingredient of cement—that is finely ground with gypsum and other chemical additives to produce cement.

Jan 07, 2015· CEMENT INDUSTRY Cement Mill Notebook QATAR NATIONAL CEMENT COMPANY DOHAQATAR 2010 na2elll . ... ~ Nael Shabana 201032~ As is known from experience, storage of cement and packing in to paper valve bags, require a reduction of the cement temperature down to about 65 ºC. Due to its high specific heat, a signifant drop in temperature ...

Aug 06, 2018· Cement Rotary Kiln, Cement Mill, Rotary Kiln, Cement Packaging Machines, Cement Ball Mills, Tube Making Machine, Cement Equipments, Heater, Cooler, Preheater Company Overview Jiangsu Haijian Stock Co., Ltd., located in Nantong, Jiangsu, is a comprehensive group corporation, who produces the complete set of cementmaking machinery for cement ...

Typically, a cement production line consists of crushing, grinding, calcining and packaging etc. Portland cement production process is very typical in the cement making. The raw materials for making Portland cement are mainly limestone and clay. In the production process, to produce 1 ton Portland cement, we need at least 3 tons raw materials.

Ash Grove also operates two deepwater import terminals west of the Mississippi, readymix concrete and aggregates operations in the Midwest, and packaging operations throughout the Midwest and West. It is the fifth largest cement manufacturer in North America, and the largest USowned cement company.

abhijith cements clinker plant in chandrapur – CathayPhillips Mining. clinker grinding units, slag cement grinding units, .Cement Mill 4 Nos and Packing Plant for Maratha Cements at Gadchandur, . dal mill project report pdf;. Click Chat Now

Other secondary additives and cementitious materials can also be added to make a blended cement. 1. GRINDING Grinding, storage, packing, dispatch 2. STORAGE, PACKING, DISPATCH 2. STORAGE, PACKING, DISPATCH :The cement is stored in silos before being dispatched either in bulk or in bags to its final destination.

A cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces is the most widely used material in existence and is only behind water as ...

Production and Maintenance planning, organizing, supervising of cement mill and packing department. Auditing and checking every machine capacity, running hour, machine down time on daily basis.

The high concentrations of suspended particulate matter of 375 μg/m 3, 338 μg/m 3, and 290 μg/m 3 recorded at the cement mill, packing house and raw mill respectively were above WHO limits. Thus, Suspended particulate matter was found to be the most significant air pollutant in Benue Cement Company factory.

Aug 30, 2012· This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite.

offers 10,353 cement packing plant products. About 7% of these are dry mortar machines, 3% are other packaging machines, and 2% are filling machines. A wide variety of cement packing plant options are available to you, such as free samples, paid samples.

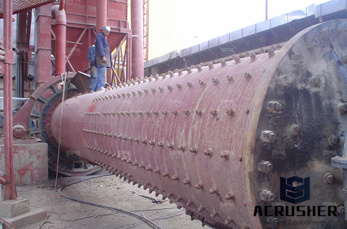

Manufacturer of High Chrome Castings Cement Mill Liners And Diaphragms, Cement Mill Liners, Mill Liners and Haze Mags Blow Bar offered by Shilpa Alloys Private Limited, Jaipur, Rajasthan.

We are the manufacturer of Cement Plants based on VSK (vertical shaft kiln) technology and Clinker Grinding Plants upto 500 TPD capacity, include Ball Mill, Rotary Dryer, Jaw Crusher, Roller Crusher, Hammer Mill, Belt Conveyer, Bucket Elevator, Pneumatic Air Lift, Screw Conveyer, Air Slide, Beltweigh Feeder, Packing Machine and Mineral ...

Jiangsu Pengfei Group Co., Ltd is one of the leading Turnkey Cement Plant manufacturers, the manufacturing and exporting base for complete set of cement machinery equipment. Our company can take on the complete set of service such as manufacturing, installation, debugging, etc for the cement machinery, metallurgy, chemical, environment protection industry.

Analysis of material flow and consumption in cement production process ... mill, pyroprocessing tower, rotary kiln, clink cooler, and cement mill are determined to be %, ... it is dispatched ...

One Cement Mill And Cement Packing. A cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are .

WhatsApp)

WhatsApp)