Silver recovery

The section on processing silver ores also had to go. This noted that Hochschild''s Ares mine is expanding the size of its plant and has ordered five additional Gekko Systems'' InLine Leach ...

WhatsApp)

WhatsApp)

The section on processing silver ores also had to go. This noted that Hochschild''s Ares mine is expanding the size of its plant and has ordered five additional Gekko Systems'' InLine Leach ...

A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved. Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver. This process removes 93% of the gold and 70% of the silver.

Apr 24, 2017· Since at least the time of the ancient Romans, mercury has been used in the mining of gold and silver. Precious metals are usually found in nature among sand and mud and mixed with other nonmetallic elements like sulfur, a problem for miners to which mercury literally was the solution.

DOVE Dry mining equipment and machinery (Dry Minerals Processing Plants) are designed and configured for classification, concentration, separation and recovery of metals and minerals concentrate in dry mode and without the use of water. Dry processing has many advantages over wet processing except when water is actually required prior to concentration and separation.

the mining process of silverobsziezo . Silver Mining Process . Silver is mined using a number of processes. One of the most common processes of extracting silver metal for the ore is the heap leach or cyanide process. The process is most popular with many miners because it is low cost, especially when processing lowgrade ores. Read More

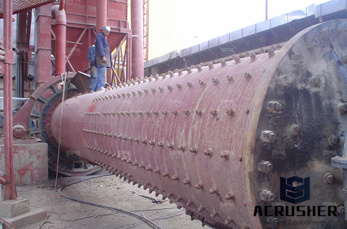

SBM supply silver mining process equipment. In China,Shanghai SBM is the famous silver ore crushing equipment manufacturer, providing silver ore crushing production line for the customer, silver mining process products are widely used in metallurgy, mining, chemicals, building materials, coal, refractory materials, ceramics and other industries.

Mining is a big part of Australia''s history, and it continues to shape the country''s economy and position in the world today. The nation is one of the world''s top producers and exporters of ...

The process of mining for silver. The process of mining for silver is broken down into three steps: removing ore from the earth, breaking it down and then flushing the silver from ore. The first step involves drilling holes in the silverrich areas geologists have previously pinpointed and .

Aug 18, 2015· Mining operations are complex. They aren''t your runofthemill type projects. These billion dollar complexes consist of various interconnected projects, operating simultaneously to deliver refined commodities like gold, silver, coal and iron ore. It''s a five stage process and we''ve broken it down using GIFs. Exploration

There are four main mining methods: underground, open surface (pit), placer, and insitu mining. Underground mines are more expensive and are often used to reach deeper deposits. Surface mines are typically used for more shallow and less valuable deposits. Placer mining is used to sift out valuable metals from sediments in river channels, beach sands, or other environments. Insitu mining ...

Gold

Successful silver mining companies are those that not only have the largest or most promising silver resources but also do the best job of controlling production following are five of ...

911MPE has small gold mining equipment for sale and more specifically mineral processing equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics. 911MPE'' offers gold mining equipment as well as processing equipment applicable to most any base metals: copper, lead, zinc, nickel, tin, tungsten and ...

the mining process of silver newstonight. Mining Process Of Silver Ores. Mining Process Of Silver Ores Silver ore Old School RuneScape Wiki FANDOM Silver ore is an item that can be obtained through the Mining skill It requires 20 Mining to obtain whilst giving 40 experience per ore After a

Silver processing, preparation of the ore for use in various products. Silver has long been valued for its white metallic lustre, its ability to be readily worked, and its resistance to the corrosive effects of moisture and oxygen. The lustre of the pure metal is due to its electron configuration,

Silver is a soft, white lustrous transition metal that possesses the highest electrical conductivity of any element, most silver is produced as a spinoff of copper, gold, lead, and zinc refining. The Silver bearing ores are mined by either openpit or underground mining methods after .

The world''s second largest bal silver mine is located in southeast Guatemala, approximately 40 km southeast of Guatemala City. Toe is mining the bal deposit by underground longhole ...

The main problem for individuals or small groups interested in hard rock gold deposits is the high capital costs both for the mining equipment to dig and remove the rock as well as the equipment to crush and process hard rock ore in order to extract the gold from its solid rock enclosure.

The dearth of silver mining is further evidentiary proof that silver is grossly underpriced – and proof that this underpricing can only be the result of ... as well as creating extended market mem in the process. My personal view, is that silver has lost some of its favour as .

The Mining Process. ... gold and silver are extracted from the ore. The processing plant alternates between treating ore from the Martha Mine open pit and from the Favona underground mine. Ore processing consists of the following stages: crushing and grinding of the ore; addition of process water (generally decanted from the tailings pond) to ...

Nov 18, 2013· The probable silver reserves of the mine as of December 2012 were estimated at The feasibility study for the silver mining project was completed in December 2012. However, the decision of when to begin operations was still pending as of November 2013. Vancouverbased mining company Silver Standard owns Pitarrilla mine.

May 17, 2016· Smelting Silver Ore with the KK6. ... Gold mining in the Yukon: Gold panning, sluicing, and more. ... Ancient gold smelting rare today. extract recovery process of refining gold to remove any ...

The Silver Extraction Process. The Silver Extraction Process. The ore used to extract silver was not a silver ore but Lead Sulphide (formula PbS), known as Galena or Galenite (named by the Roman Pliny) which contains 87% lead.

Dec 27, 2011· Ever wonder where we get silver from? Is it dug up in 100 oz bars out of the rocks? You probably know that silver is a metal that''s mined and then somehow refined to form the pure coins and bars we trade as bullion, but would you like to know a little more about that process?

WhatsApp)

WhatsApp)