Ringgeared mill drives Grinding | ABB

We provide optimized mill drive solutions for all types of ringgeared mills: low and high speed, single and dual pinion, with and without a gearbox — all designed for .

WhatsApp)

WhatsApp)

We provide optimized mill drive solutions for all types of ringgeared mills: low and high speed, single and dual pinion, with and without a gearbox — all designed for .

offers 1,176 gearbox for ball mill machine products. About 3% of these are gearboxes, 3% are speed reducers. A wide variety of gearbox for ball mill machine options are available to you, such as planetary, worm, and helical.

Horizontal Ball MIll Drives. ... Designed to deliver exceptional levels of performance and value, David Brown Santasalo ball mill drives are optimised for primary and secondary grinding applications. Extensively field tested and proven in harsh cement applications, our mill drive gearboxes cover all grinding applications up to 10MW per drive ...

Nov 30, 2015· If the rate of feed increased, coarser product will be obtained and if speed of rotation is increased the fineness for a given capacity is increases. During grinding, the balls themselves wear and are continuously replaced by new ones so that mill contains balls of various ages. Ball mill produces 1 to 50 ton/hr of powder and energy requirement ...

Helical Gearbox Standard Applications. For applications > 50KW Agitators, Conveyors, Crushers, Cranes, Larger Ball Mills, Mixers, Aerators, Fin Cooler Drives, Kneaders, Thickeners Case hardened and Profile ground Steel Gears with inclined tooth to transmit the torque between parallel / Right Angle shafts with minimum noise.. Industries Covered Sugar, Cement, Paper, Solvent Extraction, Rubber ...

TECHNICAL AND COMMERCIAL BENEFITS OF GEARLESS MILL DRIVES FOR GRINDING APPLICATIONS M. rens, ABB, Switzerland ... numerous GMDs for ball mills and SAG mills have been installed in the ... free from circulating current.

A vibration survey was carried on this Ball Mill with a duel pinion drive. The vibration is high in all planes on both sides of the Mill or both pinion drives. The measurements were similar in velocity on the motor, gearbox and both pinion bearings. The recommendations for repairs was .

May 06, 2019· Sealing grease for rubber seals on gear covers or housings of neck or shoe bearings of ball mills Vertical mills Main drive gearboxes Selection of mineral or synthetic oil and viscosity according to OEM recommendations, design, operating conditions and preferences.

RETSCH frequently hosts live webinars for existing and potential customers. For those who are unable to attend, we supply webinar screen recordings (videos), which may be watched at any time. To access the webinar videos, please let us know your contact information.

Ideal for large quantities. The Planetary Mill PULVERISETTE 5 classic line with 4 working stations delivers fast and reliable, due to the particularly highenergy effect of the grinding balls, lossfree grinding results of hard, mediumhard, soft, brittle, tough and moist materials down to colloidal on the desired final fineness, can the grinding be performed dry, in ...

ball mills. Loesche , Germany, has ... efficiency and mill availability. The software platform is installed on a PC and interfaces with common PLC systems. ... wear on gearboxes and other major components – but the continuous monitoring of the mill process allows for

Jun 05, 2013· We provide optimized mill drive solutions for all types of ringgeared mills: low and high speed, single and dual pinion, with and without a gearbox — all designed for reliable, long life and ...

Rolling Mill Drives. David Brown Santasalo has extensive experience in the design and manufacture of primary drives for pinion stands, for both hot and cold rolling mills and for new and existing applications. We can offer total design flexibility, tailoring each gearbox to a specific application.

for all types and mix of equipment gearboxes for ball mills, rotary klins, Crushers, conveyor belts, shovels, draglines and gearboxes for mixers and more we rebuild them back to Specs we first start by disassembling your gearbox, then steam clean your damage gearbox then carefully inspect all the gears, pinions, shafts, and housings,

The excellent quality of our machining and inspection facilities also insures smooth operation of the helical bevel gearbox at all times. Our helical bevel gearboxes come in a range of mountings and shaft options to suit your specific application requirements. We also provide bevel gears for your gearbox for special applications.

03 Ball Mill EDM Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This poerpoint is about the ball mills .

Keeping in line with it`s strategy of " Gearing The Future " Elecon presents the EOS Series – answer to industry needs. The EOS seri

HORSBURGH SCOTT OFFERS THE INDUSTRY''S LARGEST AND MOST EXPERIENCED TEAM OF ENGINEERS FOR GEAR AND GEARBOX DESIGN AND MANUFACTURING. ... BALL MILL DRIVES. We manufacture, repair, and install ball mill drives with improved performance and longer life. ... DOWNLOADS Cement Horsburgh Scott Capabilities Rebuild Repair Quality Brochure Reshelling.

BALL MILL GEARBOX PROBLEM BACKGROUND INFORMATION OBSERVATIONS: •Concern was expressed over the gearbox and Ball Mill at a power plant. •Black grease was noticed at the couplingend pillow block bearing as well as a loose bearing nut. .

As a key piece of equipment in mineral processing, ball and SAG mills are used to reduce bulk materials into smaller pieces by grinding. With a range of different sized and powered mills, MACA Interquip can cater to a range of projects. Whether your project is large or small we can supply either new or used mills to suit your needs.

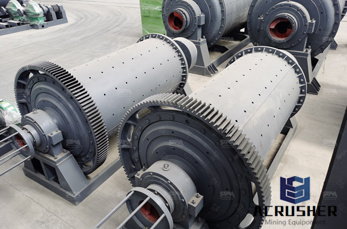

Ball mills Ball mills vary in their details and size but the basic design consists of a horizontal hollow cylinder, with an abrasionresistant interior, that rotates about its central axis. The grinding is performed by stone, metal or rubber balls that are free to move in the cylinder (Figure 1). The balls form around 40 to 45 percent of the load.

Free Online Library: Grinding mills. (mill design and leading mill manufacturers) by "Mining Magazine"; Business Business, international Petroleum, energy and mining Ball mills Design and construction Crushing machinery Mineral industry Equipment and supplies Mining industry Directories Size reduction (Materials) Size reduction of materials

designed a Denver Ball Mill that can be transported to these faraway and relatively inaccessible properties, either by the age old "muleback" transportation system. or by the modern airplane. As a result these properties may now ob tam a welldesigned ball mill with the heaviest individual piece weighing only 350 pounds.

GEAR COUPLINGGEAR COUPLING. Order Today ! Phone / Fax / Visit / GEAR COUPLING ... ROD AND BALL MILLS Reducer, with final drive Machined Spur Gears ... Strip Mills .....Refer to Factory Temper Mills.....Refer to Factory Cooling Beds Drawbench Feed Rolls Blooming Mills ...

WhatsApp)

WhatsApp)